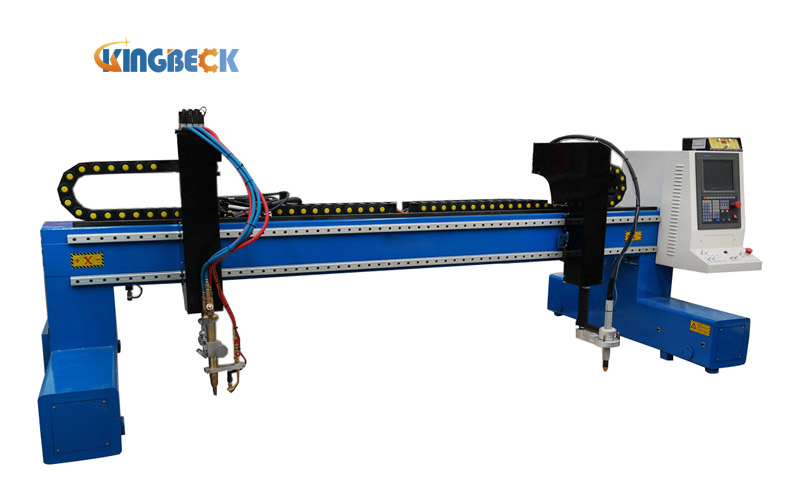

What is CNC Plasma Cutting Machine?

CNC plasma cutting machine is metal cutting machine with the help of plasma cutting technology. Plasma cutting machine utilizes high-temp plasma arc heat to make metal parts of workpiece melt and evaporate.

CNC Plasma Cutting Machine Features

1. CNC plasma cutting machine has many advantages of operation easily, high accuracy, high efficiency, low labor intensity, etc. It is widely applied for many processing workpieces. CNC plasma cutting machine has wide use in many industries, such as chemical machinery, automobile industry, general engineering machinery, etc.

2. CNC plasma cutting machine easily cut those materials that can not be cut by tradition ways or machines. When cutting small thickness plain carbon steel sheet, cnc plasma cutting speed is several times as fast as a traditional oxygen cutting speed.

3. While CNC plasma cutting machine operating, it is small probability to appear thermal deformation, with more smooth and stable cutting surface.

CNC Plasma Cutting Applications

CNC plasma is widely applied for automobile, locomotive, pressure vessel, chemical machine, nuclear industry, general machine, engineering machine, steel structure and other industries. CNC plasma is chiefly applied to metal cutting, including some cases that other machines can not cut. All kinds of different metal materials can be cut including stainless steel, alloy steel, carbon steel, copper and other non-ferrous metal materials.

According to requires, the machine cuts metal plate to complex shapes. It has features of no deformation, simple, energy saving, no noise, fast cutting speed, bright cutting hole and no need to polish.

CNC Plasma Cutting Machine Parameters

| Power Supply Brand | |||

|---|---|---|---|

| China Huayuan | USA Hypertherm | ||

| Cutting Thickness | Cutting Thickness | ||

| 63A | 0-8mm | 45A | 0-8mm |

| 100A | 0-15mm | 65A | 0-10mm |

| 120A | 0-20mm | 85A | 0-12mm |

| 160A | 0-30mm | 105A | 0-18mm |

| 200A | 0-40mm | 125A | 0-25mm |

| 200A | 0-30mm | ||