Project Description

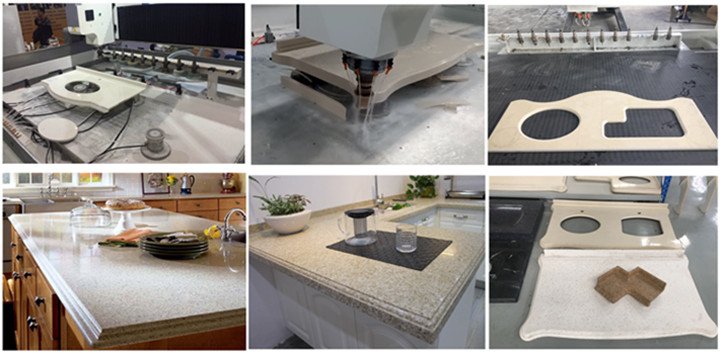

Machine Photo

Quartz Stone Sink Cutting Polishing CNC Machine is a cnc machining center that can make profiling, cutting, milling, polishing,engraving etc. It is especially suitable for the processing of quartz counter tops, sinks, wash basin hole and other opposite stones, ceramics, glass and micro crystalline stone.

Machine Features

1. Quartz Stone Sink Cutting Polishing CNC Machine is researched and developed by our company independently. Stone countertop polishing cnc router can do many process such as polishing for back splash, former anomalous edge, cutting and polishing water tap hole through the automatic tools change.

2. It’s high efficiency and low cost.For example, it just takes 30 minutes to auto-processing 2.44*0.75mquartz stone board.Processing per meter just costs about 1 RMB.

3. Stone countertop polishing machine can also be used for processing washing pool and European background wall.To process high-quality products,this model is a necessary equipment for the well-known brand who process counter-top.

Technical Parameters

| X,Y,Z Working Area | 2500*1300*400mm |

| Movement Structure | X,Y German Gear and Rack , Z Germany Ball Screw |

| Guide Rail | Taiwan Hiwin Linear Guide 30mm for X.Y.Z Axis |

| Motors&Drivers | Japan Yaskawa 850W Servo Motors & 1.0KW Servo Drivers |

| Spindle Power | 5.5KW Water Cooling Spindle |

| Spindle Speed | 0-24000rpm/min |

| Working Speed | 0-45000mm/min |

| Control System | Taiwan Syntec 6MB Control System |

| Command code | HPGL, G-code |

| Working precision | 0.05mm/300mm |

| Power Supply | AC380V-/220V-three phase(optional) |

| Compatible software | Type3/Artcam/UG/pro-E/Mastercam/UcancamV8 |

| Gross Weight | 4500KGS |

Machine Application

1. Suitable for cabinets artificial stone, quartz stone counter tops and sink.

2. European style edging, and other heterosexual stone, ceramics, glass and ceramic stone drilling, sanding, edge down, carving.

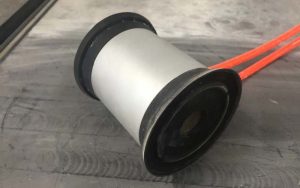

Machine Main Parts

Working Samples