Project Description

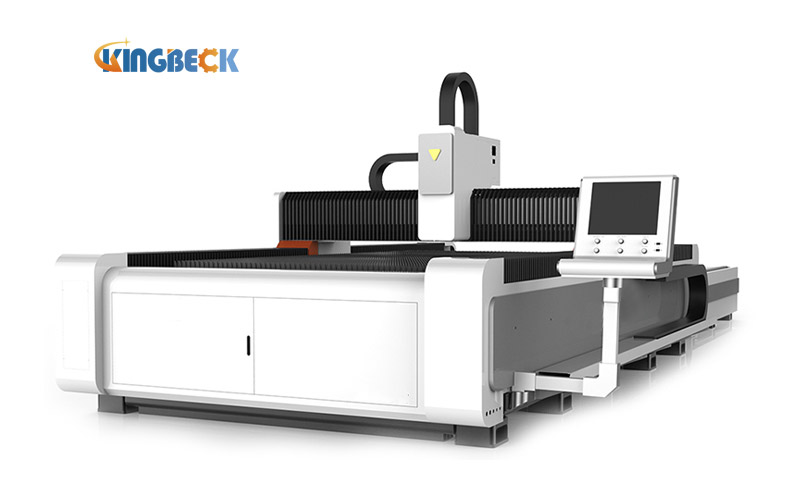

Machine Photo

Machine Features

1. Adopt German IPG fiber laser source or American SPI Fiber laser source, 150000 hours long service life and high cutting speed 15m/min;

2. Japan YASKAWA Servo motor with double ball screw driving system, ensure high precision cutting effect ,especially comparing with the single driver system.

3. Imported world famous “LaserMech” laser head with auto focusing height follower, which can ensure the constant distance between cutting head and workpiece.

4. The machine cutting slot is very slim, can reach up to 0.05mm. It is very suitable to process precision parts with high efficiency.

5. Automatic Lubrication System: can lubricate the linear guiderail automatically, nearly 500 times per minute to promise the machine high working precision.

6. Convenient Collecting System, which has the special funnel design to make collecting easier.

Machine Parameters

| Laser Power | 1000W |

| Laser Source | Germany IPG (First brand ) |

| Laser Type | Fiber Laser |

| Laser head Technology | Germany Technology |

| XYZ Working area | 1500*3000 mm*150mm |

| Carbon steel | 10mm |

| MAX cutting speed | 30m/min |

| Laser wavelength | 1070nm |

| Minimum line width | ≤0.1mm |

| Location precision | ≤±0.05mm |

| Re-location precision | ±0.02mm |

| Max. moving speed | 40m/min |

| Supporting Format | PLT, DXF, BMP, AI |

| Power demand | 380V/50Hz/60HZ/ 3 phase |

| Cooling Way | Water Cooling |

| Worktable max. load | 3500KGS |

| Transmission Method | Ball Screw Transmission |

| Table-driven system | Japanese Imported Panasonic Servo Motor & Driving System |

| Focus Method | Following and Automatic Adjust Focus |

| Control Method | Offline Movement Control |

| Control software | Baichu Professional Laser Cutting Software |

Professional Solution

| carbon steel | cutting thickness(mm) | cutting speed(m/min) |

| 500w | 1~6 | 0.6~12 |

| 750w | 1~10 | 0.6~15 |

| 1000w | 1~12 | 0.6~18 |

| 2000w | 1~8 | 0.7~40 |

| stainless steel | cutting thickness(mm) | cutting speed(m/min) |

| 500w | 0.5~4 | 1.2~20 |

| 750w | 0.4~4 | 0.6~25 |

| 1000w | 0.4~5 | 0.6~30 |

| 2000w | 0.4~12 | 0.7~40 |

| galvanized sheet | cutting thickness(mm) | cutting speed(m/min) |

| 500w | 1~3 | 0.6~6 |

| 750w | 1~3 | 1.5~20 |

| 1000w | 1~3 | 1.5~20 |

| 2000w | 1~3 | 5~35 |

| brass | cutting thickness(mm) | cutting speed(m/min) |

| 500w | 0.8 | 3~3.5 |

| 750w | 0.8~1.5 | 1.5~3.5 |

| 1000w | 1~3 | 1.2~15 |

| 2000w | 1~3 | 3~25 |

| Aluminum | cutting thickness(mm) | cutting speed(m/min) |

| 500w | 1~2 | 0.9~3 |

| 750w | 1~3 | 1~8 |

| 1000w | 1~3 | 1.2~10 |

| 2000w | 1~8 | 0.8~35 |

Machine Application

♦ Applied materials:

Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

♦ Applicable Industry:

This machine is widely used in various industries such as advertising decoration,kitchen ware,engineering machinery,steel and iron,automobile,metal plate chassis,air-conditioner manufacturing,metal plate cutting,etc.

Machine Main Parts

Top Brang Cypcut Control System with Handle

Professional S&A Water Chiller

Working Samples