Project Description

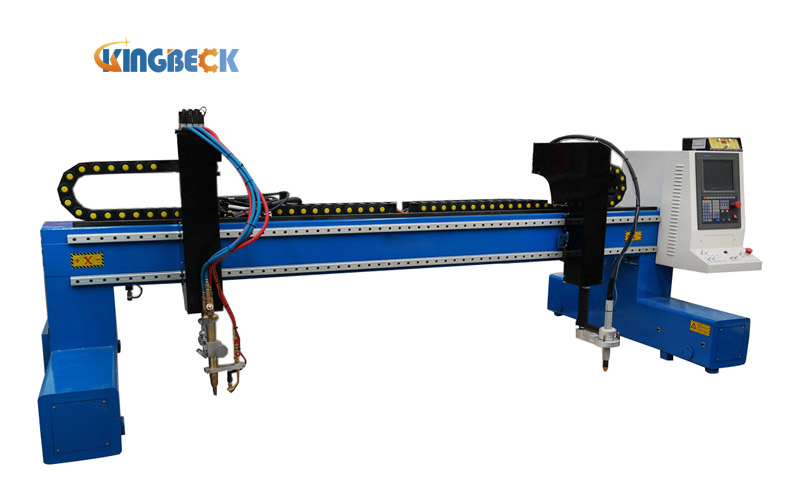

Machine Photo

Heavy Duty Gantry Plasma Cutting Machine uses double drive mode to ensure the machine work smoothly, high positioning accuracy and simple structure. Moreover, modularized design makes machine components have strong exchangeability , and function is more simply & conveniently. The user can configure plasma cutting torch in different sizes according to the process requirements. High automation, easy operation, high accuracy, high reliability, low price, and simple operation & maintenance.

Features

- Gantry box beam with good carrying capacity, high double sides drive,For the compact structure,sufficient to eliminate the welding stress,its performance is stable and realiable.

- Independent intellectual property rights and control system with Chinese/English display, USB transmission

- Highly-precise linear guides, dual drive ensure the machine works noiselessly with high speed and high precision

- Human-computer interface design makes the machine easy to learn and operate, and have complete functions.

- Have 7 inch color LCD display and operate panel, and read program and software upgrade by USB flash driver.

- Have the function of automatically memorizing and restoring when power off.

- Have the function of wireless remote control which can control cutting at any place around the control desk.

- Cutting torch can be selected to work with plasma or flame according to your cutting requirement

Parameters

| Model | KB-1325 |

| Effective Cutting Width (X axis) | 1300mm |

| Effective Cutting Length (Y axis) | 2500mm |

| Plasma power | LGK/Hypertherm |

| Drive Mode | Bilateral-side |

| CNC system | Beijing STARFIRE CNC |

| Plasma cutting speed | 50-6500 mm/min |

| Cutting torch lifting distance | 150mm |

| Speed setting error | ≤±5% |

| Max Idle running speed | 12000mm/min |

| Torch height controller accuracy | ≤±1.0mm |

| Longitudinal line accuracy | ±0.2mm/10m |

| Motor and driver | stepper motor and driver |

| Gearbox | Hubei planet |

| Drive Method | Rack and square rails for X Y Z axis |

| Moving Precision | 0.01mm per step |

| Power Source | 380V 50/60Hz |

| Height controller(plasma) | PHC330-Arc voltage height controller for plasma cutting |

| Plasma cutting thickness | 1-32mm |

| length of a side | ±0.5mm |

| Diagonal error |AD-BC| | ±0.5mm |

| Base point return error | ±0.2mm |

| Intersection point error | ±0.5mm |

| Lineation forward- reverse error | ±0.2mm |

Machine Main Parts

Working Samples

Package

Strong and professional packing before shipment.