Project Description

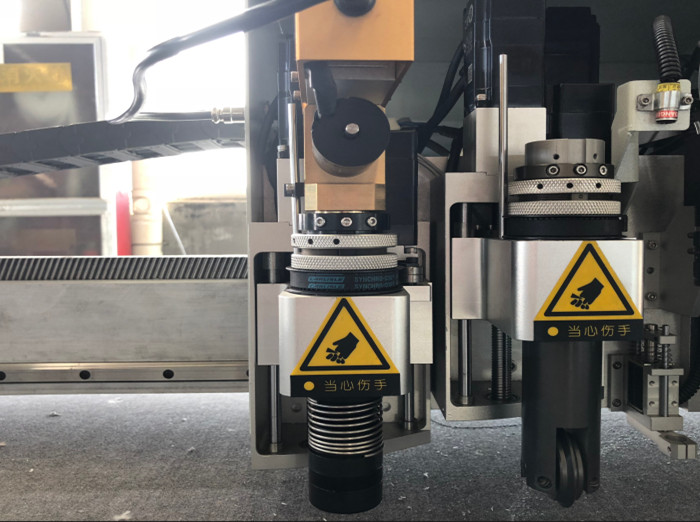

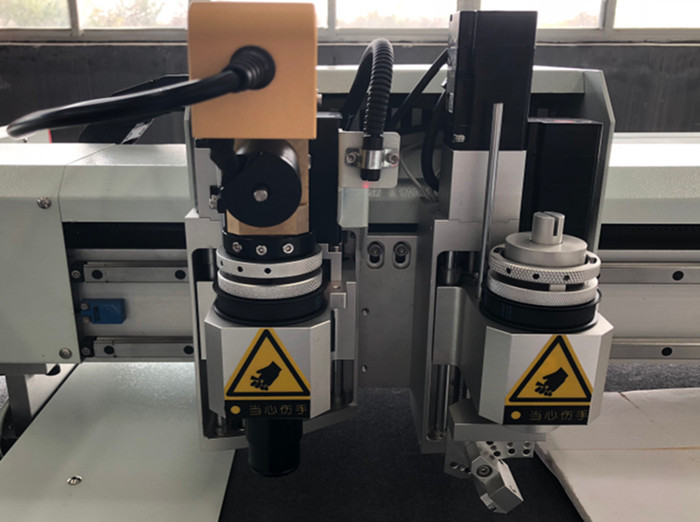

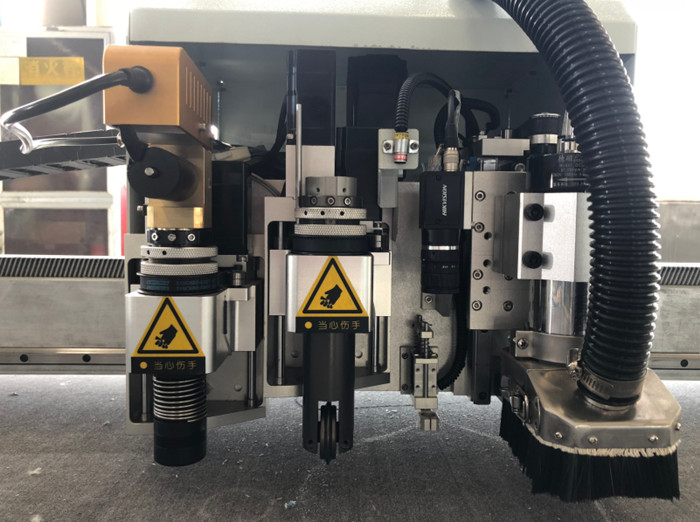

Machine Photo

Features

1. Electric shock and head are strong, and vibration frequency is high which can up to 25000 times per minute.

2. The whole machine adopts the high precision module; the response is faster; the positioning accuracy is higher; the overall performance is more stable.

3. Using Servo-motor from Mitsubishi; With computer controlling, the depth of cutting and creasing can be adjusted precisely according to the need of box designer and makers.

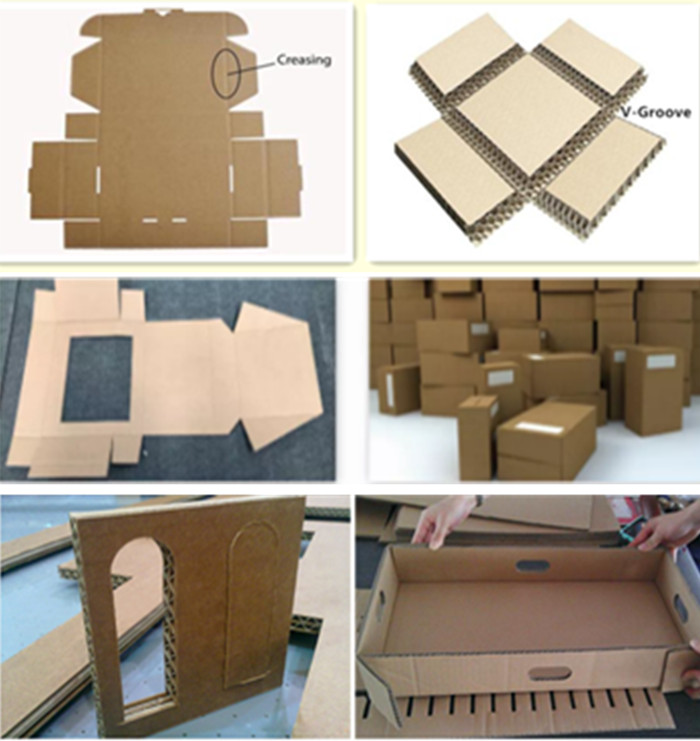

4. The machines have three types of functional heads: vibration cutting head, creasing wheels, drawing pen. It enable the machine can cut different materials; corrugated paper, gray board, white cardboard, plastic sheets, composite materials, textiles, leathers, foam board, sponge etc .

5. Drawing lines, drawing, text annotation, half cutting, full knife cutting,can be completed at the same time, which meets the low volume, multi order, multi style production target.

6. Programmable multi axis motion controller; stability and operation achieve the leading technical level at home and abroad.

7. Table mat are imported from the USA; the fiber board are durable, good permeability, and stable shape.

8. The completely independent research and development of computer control system supports remote teaching, remote maintenance, remote upgrade, let the customer use more convenient.

1.0.Red ultra-light positioning device for printed can cut accurately in easy and quickest way.

11. Any CAD software can be connected. It is widely used for plotting and cutting industries and sectors like garment, shoe making, cases, handbags, lighting fixtures, advertising gifts, self-adhesive and color box packing.

Parameters

| Model | KB-1625 |

| Max. Cutting size | 2500*1600mm |

| Power | 9.0KW |

| Motor | Servo motor |

| Multi-functional Tool Head | Thorough cutting/Kiss cutting/Creasing/Plotting/Laser Locating/Automatic Table-level measuring |

| Security configuration | High sensitive infrared induction (optional) |

| Travelling speed | Max. 1200mm/s |

| Cutting speed | Max. 800mm/s (Depending on different material type) |

| Movement speed | 1200mm/s Maximum 1200mm/s |

| Cutting speed | Maximum 800mm/s (set according to different cutting materials) |

| Cutting material | Corrugated paper, PVC expansion sheet, kt sheet, thick foam, carton board, paperboard, car sticker, adhesive Sticker, etc. |

| Cutting thickness | Maximum 5-mm (set according to different materials) |

| Material fixing method | High power vacuum absorption and intellectual partition |

| Repeated positioning accuracy | Maximum 0.01mm |

| Mechanical Precision | Maximum 0.02mm |

| Drive system | Steel wire synchronous belt , servo motor, linear guideway |

| Control system | digit RISC core cpu + large scale programmable logic array |

| Operating mode | operation platform + data output control software (operation platform can be divided into connected and separated parts) |

| Display mode | Chinese and English liquid crystal touch screen |

| Gross weight | 1230KGS |

Optional Knife Cutting Tools

EOT+Creasing Wheel

EOT+V Cutter

EOT+Creasing Wheel+CCD Camera

1. EOT( Electric Oscillating Tool)

It can cut many different materials (such as corrugated paper, cardboard, offset paper, grey board, rubber, honeycomb board, PP, PE, PVC, gasket, leather, carpet and mat )

2. Creasing Wheel

It can fold corrugated paper, card paper and offset board into perfect folding line.

3. V Cutter:

It is used for V-groove making for thick corrugated paper box.

4. CCD Camera

It is professional for cutting the printed cardboard box with different designs.

Cardboard Box Cutting Samples