Project Description

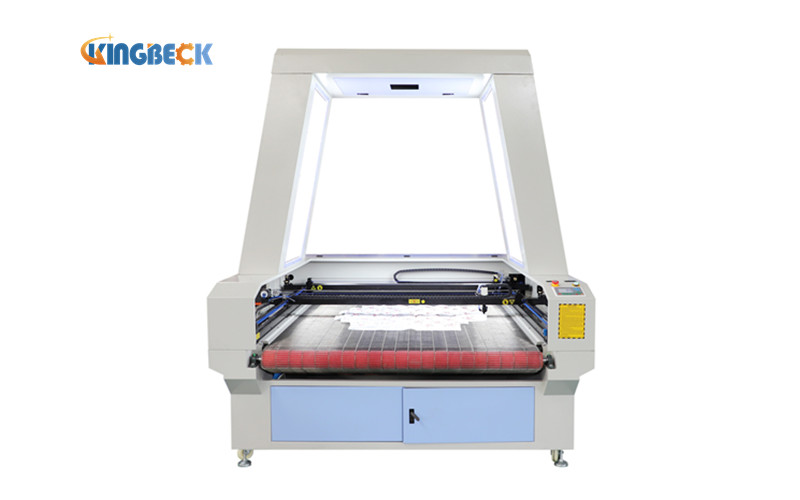

Laser Printed /Sublimation Fabric Contour Cutting Machine

Laser Printed /Sublimation Fabric Contour Cutting Machine Features

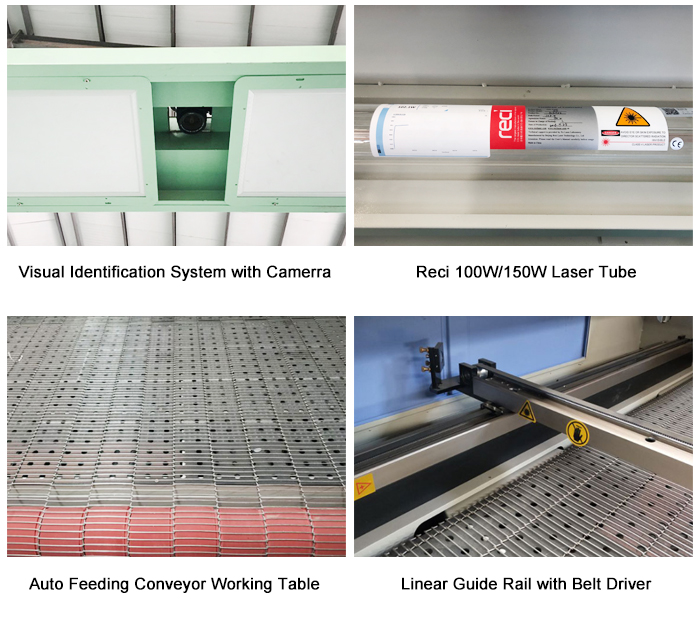

1.Adopt advanced CCD camera recognition system, put images in your PC through visual identification system ,then the images can be identified automatically with high positioning accuracy, greatly save your material and cutting time.

2.With DSP powerful data processing capability, professional camera recognition software,and the coordination between precision mechanical components, ensure the machine cutting fast and accurately.

3.Fast curvilinear cutting function: It can cut via any curve fast and consecutively,the laser head move in beautiful arc to meet different industry needs.

4.Multiple compatible software such as CAD,CORELDRAW,PHOTOSHOP etc,friendly man-machine interface, close to the industry requirements.

5.Automatic feeding and discharging, save time, improve work efficiency, it can customize according to customer’s request.

Laser Printed /Sublimation Fabric Contour Cutting Machine Parameters

| Machine Model | KB-1610C |

|---|---|

| Working Area | 1600*1000mm |

| Laser Power | 80W/100W/130W/150W for option |

| Laser Type | CO2 Sealed glass Laser tube, 10.6μm |

| Cooling Syetem | Cooling System |

| Working Speed | 0-400mm/s |

| Transmission System | Linear Guide Rail with Belt |

| Control System | DSP Control |

| Repeat Location Accuracy | ± 0.01mm |

| Working Voltage | 110V/220V 50HZ/60HZ |

| Camera View Range | 2100mm*2100mm |

| Working Table | Stainless Steel Conveyor |

| Format Support | AI/DXF/DWG/JPG/BMP/PLT/DST CorelDraw/PhotoShop/AutoCAD/Illustrator |

| Operational Software | CCD Visual Contour Cutting System |

| Operate System | Windows XP/7/8 |

Machine Working Procedure

Without the need for human intervention, Vision Laser machine can achieve continuous recognition and cutting of the entire roll printed fabrics.

※ Step 1: Various graphics printed on fabric and loaded to the laser cutter working table with our auto-feeder.

※ Step 2:Material information extracted by the HD SRL Camera

※ Step 3: The software recognize outer contour of graphics, then automatically create the cutting path

※ Step 4: Laser head cuts as the path in software

Machine Main Parts

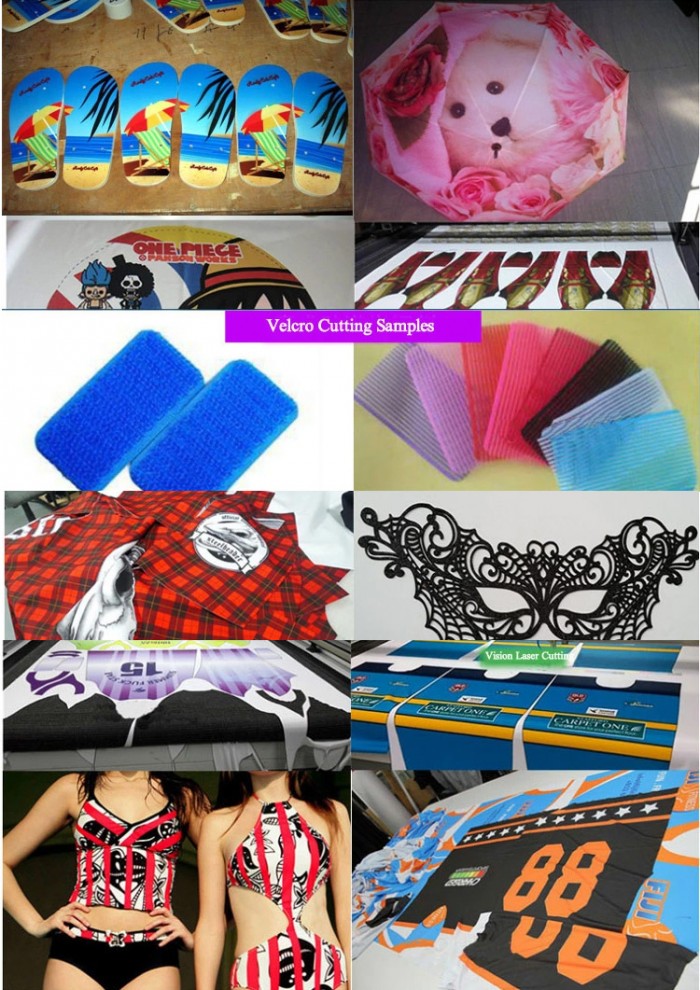

Laser Printed /Sublimation Fabric Contour Cutting Machine Application