Project Description

Machine Photo

1. Multi-functional digital cutterscan be quickly changed to cutdifferent materials.

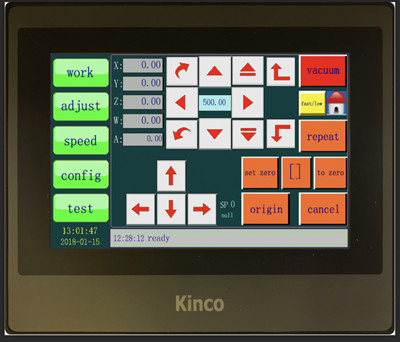

2. Kinco control system offers high-performance and convenient Ethernet with high speed.

3. English LCD touch screen panel and a massive storage volume system.

4.With the functions of making dotted lines, partial and whole disconnections, perfect backfins, laser positioning and accurate plotting.

5. The platform detection device regulates the knife pressure automatically, keep satble platform and perfect cutting.

6. Induce draft separately and small piecescan be easily cut .

7. Anti-collision and auto-sensing deviceensure machine safe working.

8. High efficiency can be realized without making a high-cost knife model.

Automatic Fabric Cutter Parameters

| Working area | 1600*2500mm |

| Material fixed way | Vacuum suction system |

| Cutting speed | 0-1,500mm/s(according to different cutting materials) |

| Cutting thickness | ≤50mm |

| Cutting accuracy | ≤0.1mm |

| Drive system | servo motor and driver |

| Transmission system | linear square rail and belt |

| Instruction system | HP-GL compatible format |

| Vacuum pump power | 9.0KW |

| Graphic format supported | PLT, DXF, AI, etc. |

| Compatible software | CORELDRAW, PHOTOSHOP, AUTOCAD, TAJIMA, etc. |

| Safety device | Infrared sensors and and emergency stop devices |

| Working voltage | AC 220V±10%, 50Hz/60Hz |

| Package | Wooden case |

| Machine size | 3550×2200×1200mm |

CNC Fabric Cutting Machine Details

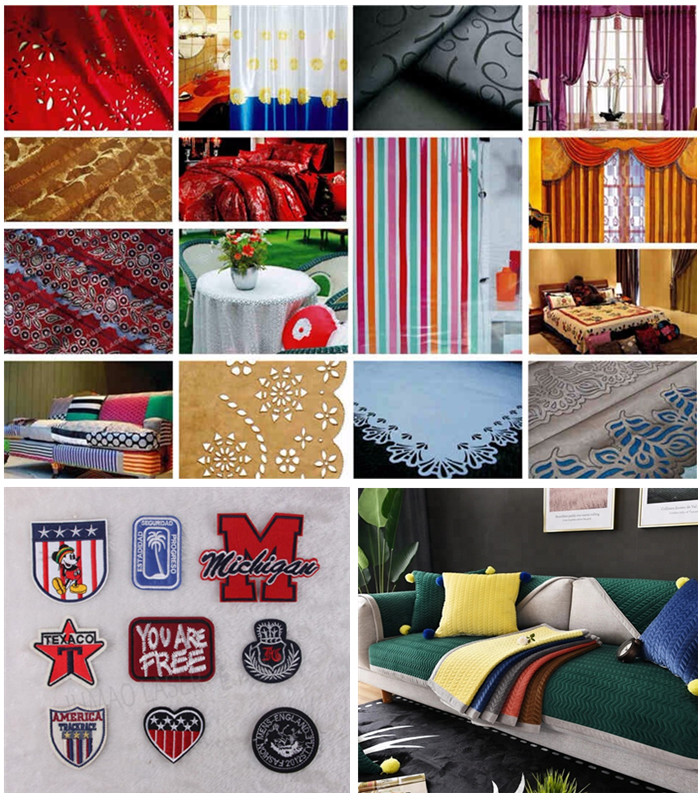

CNC Fabric Cutting Machine Applications

CNC Automatic Fabric Cloth Cutting Machine can cut fabric, leather, cardboard, plastic, paper, rubber, sponge, leather and foam, etc. It can also cut variety of gaskets,including cork rubber gasket, Non asbestos gasket, rubber gasket, graphite seal gasket, reinforced gasket without air pollution, no burnt edge. It is widely used in clothing industry, packaging protection, advertising display, terminal insulation, model&mock up making, puzzle and pattern cutting, etc.