Project Description

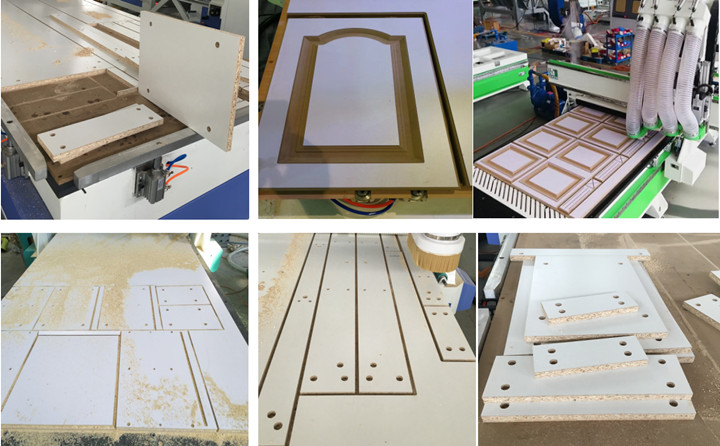

Machine Photos

We manufacture the machines according to your detailed request , such as different machine working size& functions

Machine Features

1.The heavy CNC machining center with heavy structure design, whole machine frame is produced by abrasive blasting and stress annealing treament, long-term use without deformation,high working accuracy.

2. It is suitable for gravity cutting, adopts the world’s top parts such as Italian original imported spindle and row drill, German helical rack and Taiwan Hiwin linear guide rail, with stable performance.

3. The machine control interface is humanized and easy to operate. The operator can be employed after simple training without skilled workers. The equipment can move quickly and efficiently, and your productivity can be improved.

4. It can realize automatic feeding and unfeeding, optimize feeding, vertical drilling, automatic feeding and completion without interruption, and achieve maximum efficiency output. Compared with traditional feeding, it only needs one person to operate, and even one person can operate multiple machines. Zero error, simple operation ,working efficiency is greatly improved.

5. Automatic labeling is optional. When the machine make cutting and drilling, the board is identified in advance and the corresponding bar code is automatically pasted on the board. No manual operation is required in the whole process, realize zero error rate.

Technical Parameters

| X,Y,Z working area | 1300*2500*300mm |

| Spindle | Italy HSD 9 kw Auto Tool Change Air Cooling Spindle 24000rpm (ISO30) |

| Tool magazine | 8 /12 Pcs ISO30-ER32 tool holders |

| Tool change time | 8 Seconds |

| Boring head | Boring unit: 5+4 vertical |

| Motor | Taiwan Syntec Servo Motor |

| Drive | Taiwan Syntec Servo Driver |

| Positional Accuracy | ±0.05/300mm |

| Max Rapid Travel Rate | 50,000mm/min |

| Max Working Speed | 30,000mm/min |

| Table Surface | Vacuum Table |

| Frame | Steel Square Tubes up to 8mm, T Type |

| X, Y Structure | Helical Rack & Gear Transmission,Hiwin 30mm Guide Rail |

| Z Structure | TBI 3210 Ballscrew, Hiwin 30mm Rail Linear Bearing |

| Control System | Taiwan Synetc Control System |

| Command Languages | G Code |

| Software Compatibility | Artcam English version/Type3 |

| Dust Collector | 3.0KW double bags |

| Working Voltage | AC380V/3Phase/50HZ |

Applicable Industry and Material

Furniture industry: Panel furniture, cabinet furniture, office furniture, customized furniture, solid wood furniture,

Wood industry: speakers, game cabinet, computer desk, sewing machine, Musical Instruments

Plate processing: insulation parts, PCB; Dynamic car body, bowling track, staircase, anti – doubling board, epoxy resin, ABS, PP, PE and other carbon compounds

Main Parts

World Top Brand HSD ATC Spindle from Italy

9.0KW HSD spindle + Taiwan 8/12 pieces tool magazine. It can change the tool bits automatically one by one according to different work orders, no need manual tool change

Italy HSD Drilling Unit

5 vertical + 4 horizontal, it can making drilling in both horizontal direction and vertical direction Professional for kinds of cabinet profile drilling and assembling.

Auto Loading Platform

It can load your workpiece automatically, no need hand feeding, save time and improve working efficiency.

Auto Unloading Platform

It can unload the finished workpiece automatically together, no need manual work, save labor cost.