Project Description

Machine Photos

Machine Features

- Diversified control processing speed can control the working speed, traveling speed and dropping tool speed, and it improves the quality and efficiency greatly.

- Humanized and beautiful designing. Break point specific memory to keep the carving status when power off, processing time forecast and other functions in case of the accidental power outages. Stop Emergency Buttons , emergent shutdown during unexpected accidents and do no harm to human. The intelligent processing cross-border protection function can prevent the excessive process caused by mechanical collision. Strong Machine Body, reliable and durable, with long working life.

- Top-quality components, to make the machine high-precision and high-efficiency. HSD ATC spindle, Delta inverter, TBI ball screw, Yaskawa servo motors , OSAI control system and so on, which keep the machine in best condition even after working for many years.

- Easy and safe operation and low maintenance cost. To make you learn quickly how to operate safely the machine, free training in our factory will be offered. Less time and less money will be cost on the maintenance because of the top quality of the machines.

- Many optional configuration and OEM service available. According to your requirement, different configurations will be offered.

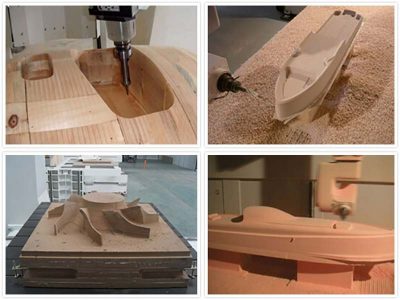

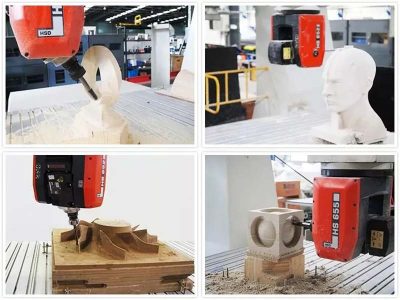

Machine Application

- Mold industry: Various large metalloid molds, especially suitable for automotive foam mold, wooden ship model, wooden model aviation, rail wooden mold and wooden mold train. Instrument industry: 3D surface carving and shape cutting of large-scale instruments.

- Furniture industry: suitable for processing cabinet door, wooden door, solid wood furniture, stereo box, computer desk, game cabinets,etc.

- Decoration industry: acrylic, PVC, density board, stone, organic glass, soft metals like aluminum and copper etc.

Technical Parameters

| Model | KB-1224 5 axis cnc router |

| Movement type | Movable table |

| X working area (MM) | 2400 |

| Y working area (MM) | 1200 |

| Z working area (MM) | 900 |

| C travelling | ±213° |

| A travelling | ±120° |

| Beam spacing(MM) | 4260 |

| Beam Height(MM) | 2150 |

| Vacuum pump | Germany Becker pump |

| Supplier for Double pendulum head | 10.0 KW Italian HSD |

| Range of speeds | 22000 RPM/min |

| Servo Motor brand | YASKAVA |

| Table size (MM) | 1200*2400 |

| Product fixed form | Vacuum table |

| Tool magazine | 8 positions Carousel Tool Storage |

| Control system | OSAI |

| Machine size | 3600*4000*3500mm |

| Total weight | 12T |

| Total Power(kw) | 24KW |

| Voltage | AC380V/60HZ |

| Maximum lifting weights | 20T |

| File exchange | G code |

| X Axis Maximum speed | 45m/min |

| Y Axis Maximum speed | 45m/min |

| Z Axis Maximum speed | 20m/min |

| C Axis Maximum speed | 20m/min |

| Aaxis Maximum speed | 20m/min |

Machine Details