Project Description

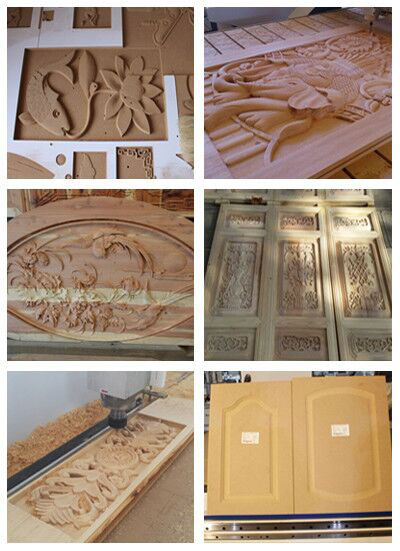

Machine Photo

Machine Configuration

1. 1300*2500*200mm working area

2. 4.5kw HQD Air cooling spindle 0-18000rpm/min

3. Stepper motors and Leadshine driver, Yako driver is optional

4. Fuling inverter , Delta inverter is optional

5. DSP A11 control system , Ncsudio system is optional

6. Vacuum and T-slot working table

7. Y.Z axis with Germany Helical gear rack, Taiwan Hiwin guide rail, Z axis TBI ballscrew

8. Automatic Tool Calibration, auto lubrication system

9. 3.0kw dust collector system

10. Artcam, Type3 software

Technical Parameters

| Model | KB-1325 (1530 / 2030 / 2040 option) |

| XY working area | 1300*2500mm |

| Z working area | 200mm |

| Work-holding | Vacuum working table |

| Interface | USB |

| Command | G code*.u00*.mmg*.plt |

| reposition accuracy | ±0.05mm |

| software | DSP / Ncstudio / Mach 3 |

| Power(exclude the spindle) | 1840W |

| Power | 220V/380v; 50/60Hz |

| Spindle power | 4.5KW air cooling |

| Main axle rotating speed | 0-18000rpm |

| Work Mode | Stepper motor |

| Transmission | XY-High precision Gear transmission; Z- ball screw transmission |

| Guide rail | Taiwan square guide rail |

| Machine size | 3100*1700*1500mm |

| Packing size | 3230*2230*1900mm |

| N.W | 1200kg |

| G.W | 1500kg |

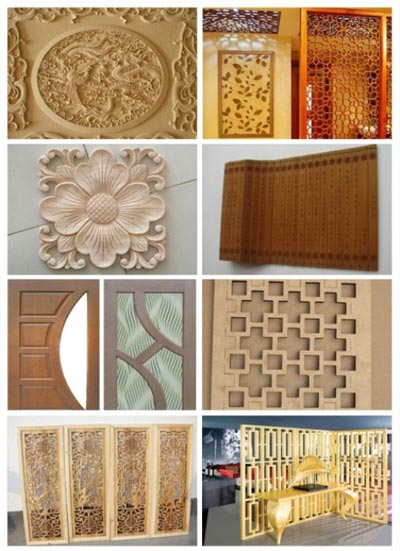

Machine Application

1. Furniture industries: woodworking,cabinet doors, wooden doors, solid woods, plates, antique furniture, doors, windows, desks and chairs.

2. Decoration industries: screens, wave boards, large-size wall hangings, advertising boards and sign making,3d art design.

3. Arts & Crafts industries: Engrave on artificial woods, bamboos, organic boards, double-color boards and so on for achieveing effects of exquisite patterns and characters.

4. Processing material: engraving, milling and cutting processing for acrylic, PVC, density boards, artificial stones, organic glass, plastics and soft metal sheets such as copper and aluminum.

Working Samples