Project Description

Machine Photo

Machine Features

1. The lathe is founded by industrial pipe welding, box-type structure to ensure the high stability.

2. The special instruments to eliminate welding stress, high-precision machining planer ensure the precision and no deformation

3. The major machine body makes the stability and no shacking in high speed

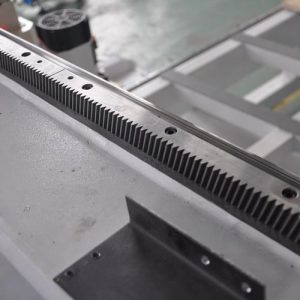

4. X.Y.Z all apply imported screw, high precision gear frame and linear square guide, ensure the high accuracy.

5. The professional mechanical design, scientific structure and generous appearance

6. X.Y.Z axis use anti-dust system, prevent dust during working, make sure the long lifespan of spare parts.

7. High quality driver motors, spindle motors, cables, inverters,etc

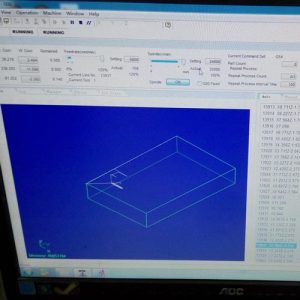

8. Professional CNC control system,can compatible with many kinds CAM software, such as Type3/ARTCAM/UG/PRO-E/

MASTERCAM.

9. It can be customized more large format and special format models, and it can be optional standard configuration spindle

or importing, auto-change tool system, oil lubrication system, vacuum inhaling and dust collect etc.

Application

1. Wood Furniture Industry: Wave Plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates, cupboard doors, interior doors, sofa legs, headboards and so on.

2. Advertising Industry: Advertising identification, sigh making, Acrylic engraving and cutting, crystal word making, blaster molding, and other advertising materials derivatives making.

3. Die Industry: A sculpture of copper, aluminum, iron and other metal molds, as well as artificial marble, sand, plastic sheeting, PVC pipe, wooden planks and other non-metallic mold.

Machine Parameters

| Working Area | 1300mm*2500mm*200mm |

| Table material | Thicken welded steel Bed, Aluminum Alloy table |

| X,Y,Z Guideway rails | Square guide rails Taiwan HIWIN, rack transmission |

| Max Engraving Speed | 45000mm/min |

| Resolution ratio | 0.002mm |

| Repetition accuracy | ±0.02mm |

| Spindle power | 3.2KW Water Cooling Spindle |

| Spindle Rotating Speed | 0 -24000rpm/m |

| Spindle cooling | Water Cooling |

| Control System | DSP Control System |

| Drive motor system | Stepper Motor and Leadshine Driver |

| Engraving Command | G code, u00, mmg, PLT, HPG |

| Operational Software | Original Type3 Software, ArtCam software |

| Software Compatibility | Support CAD/CAM software, PLT format, Corel Draw,etc |

Machine Main Parts

3.2KW Water Cooling Spindle

Taiwan Hiwin Square Guide Rail

Germany Helical Gear Rack

Fuling Inverter

Leadshine Inverter

Stepper Motors

Ncstudio Weihong Control

Taiwan TBI Ballscrew

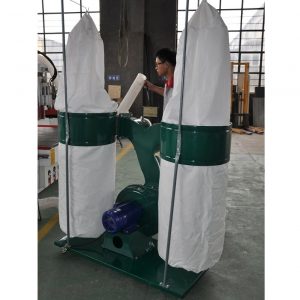

3.0KW Dust Collector

Working Samples