CNC Vibration Knife Cutting Machine is widely used for cutting leather, cardboard, fiberglass, corrugated board, self-adhesive, film, foam board, acrylic board, rebound rubber, rubber cloth, gasket material, clothing cloth and footwear materials. Some composite materials such as PU, EVA, XPE, PVC, PP, PE, PTFE, ETFE can also be cut easily.

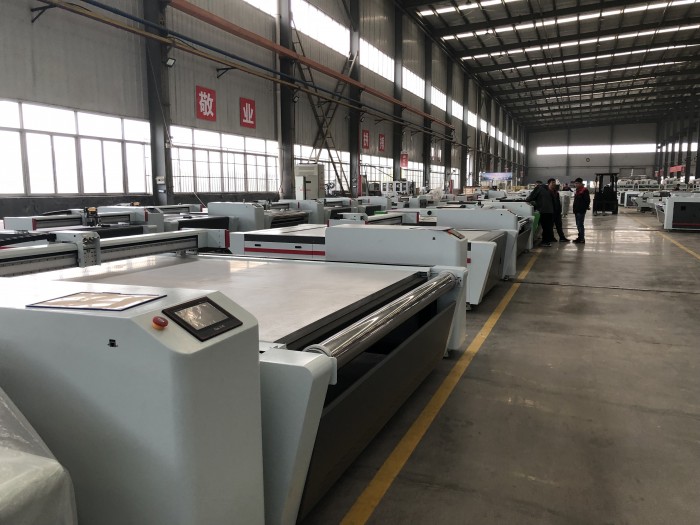

CNC Vibration Knife Cutting Machine produced by KINGBECKadopt ultra-high frequency vibration knife cutting technology. The vibration knife with strong power and high vibration frequency that can reach 25000 times per minute. With this machine , you don’t need to make molds, so we can save production cost and working time.

KINGBECK CNC Vibration Knife Cutting Machine adopt imported PMI / HIWIN square linear guides rail driving system, Japan Yaskawa servo motor and drivers ensure high precision and fast cutting speed. The cutting accuracy can be completely zero-to-origin due to the linear guides. Meanwhile the vibration knife cutting machine eliminates the irregularity of manual cutting. The machine stability and operability reached the leading technology level at home and abroad.

Compared with common laser cutting machine, the CNC Vibration Knife Cutting Machine has no air pollution and does not form burnt edge or produce odor. And the cutting speed is 5-8 times faster than that of the laser cutting machine.

In addition, the drawing function in CNC Vibration Knife Cutting Machine allows users to draw a variety of high-precision patterns. The application of the Ethernet port makes the cutting plotter quick and convenient to use. Meanwhile, the data-based operation can enhance the production management of the enterprise. Drawing lines, half-knife cutting and full-knife cutting can be done at one time by this machine. The usage of intelligent lofting, automatic stepping and automatic cutting system let the man-machine cooperation come true.

Moreover, the CNC Vibration Knife Cutting Machine is easy to be installed, set up and operated. Its special safe sensing device conforms to European standards. And the humanized control interface which is ready to learn offer s customers more peace of mind.